Clamping technology

Workpiece Clamping

For decades, Ortlieb has stood for maximum precision in clamping technology.

Our workpiece clamping systems enable safe, repeatable clamping processes - from manual workpiece clamping to fully automated solutions.

The focus is always on one thing: maximum process reliability and durability with minimal maintenance.

Everything for the reliable machining of workpieces: Our SPANNAX®, QUADRO® and VarioLine® brands offer high-performance for a wide range of applications.

Whether dead length collet chucks, clamping heads, collets, chuck sets, or HSK chuck sets – Ortlieb offers the right clamping system for every production process.

Our products cover the entire spectrum – from classic lathes and milling machines to modern automation solutions.

All components are precision-manufactured and guarantee consistently high clamping forces, even under continuous load.

Thanks to decades of experience in clamping technology, we understand the requirements of industrial manufacturing processes down to the last detail.

Our solutions are modular in design and can be easily integrated into existing systems – even as special designs according to customer specifications.

Clamping technology with strong brands – for every application

Our brands SPANNAX®, QUADRO® and VarioLine® stand for high performance, precision, and reliability in industrial workpiece clamping.

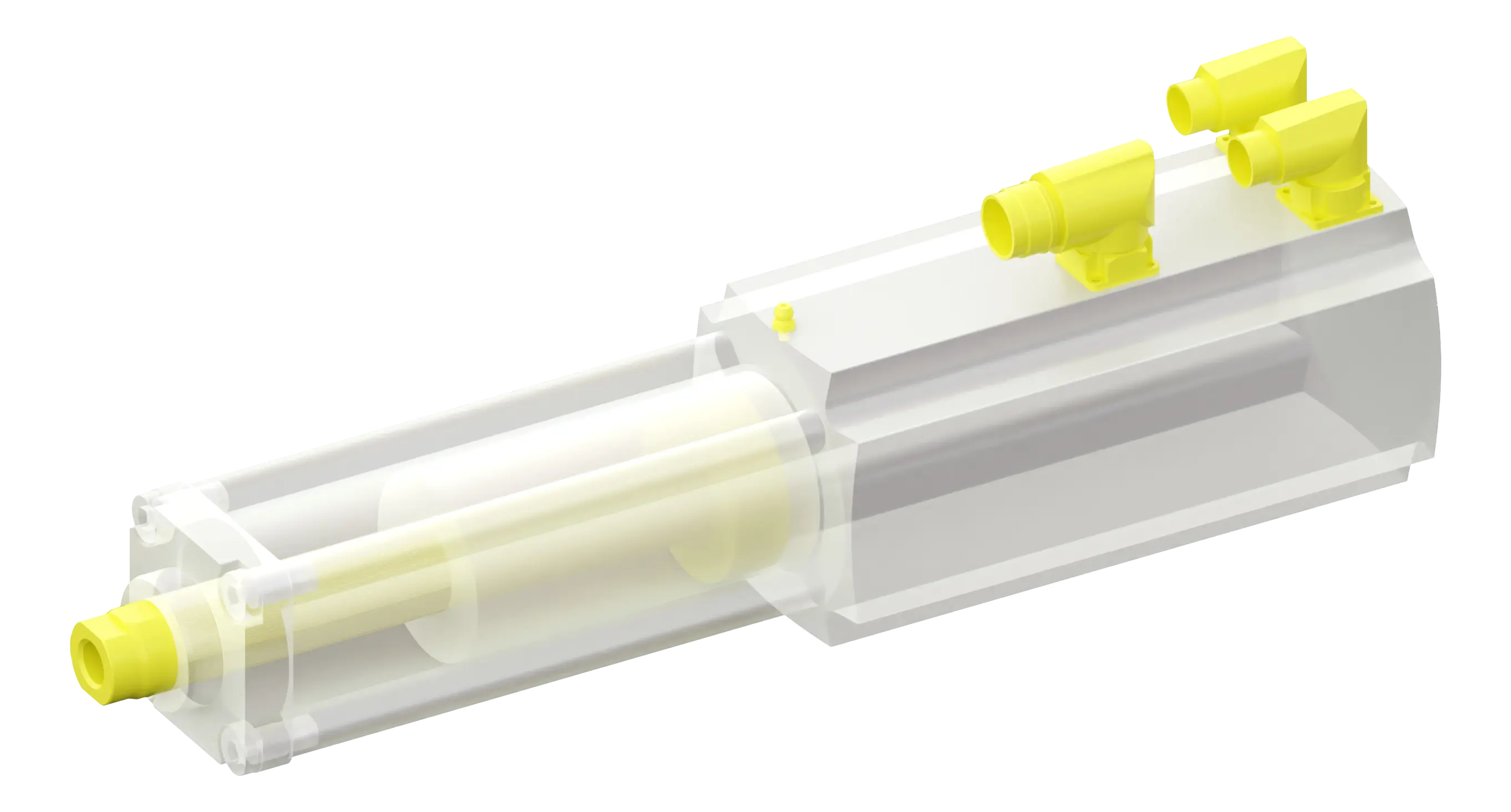

SPANNAX®

The perfect choice for use in turning, milling and rotary transfer machines

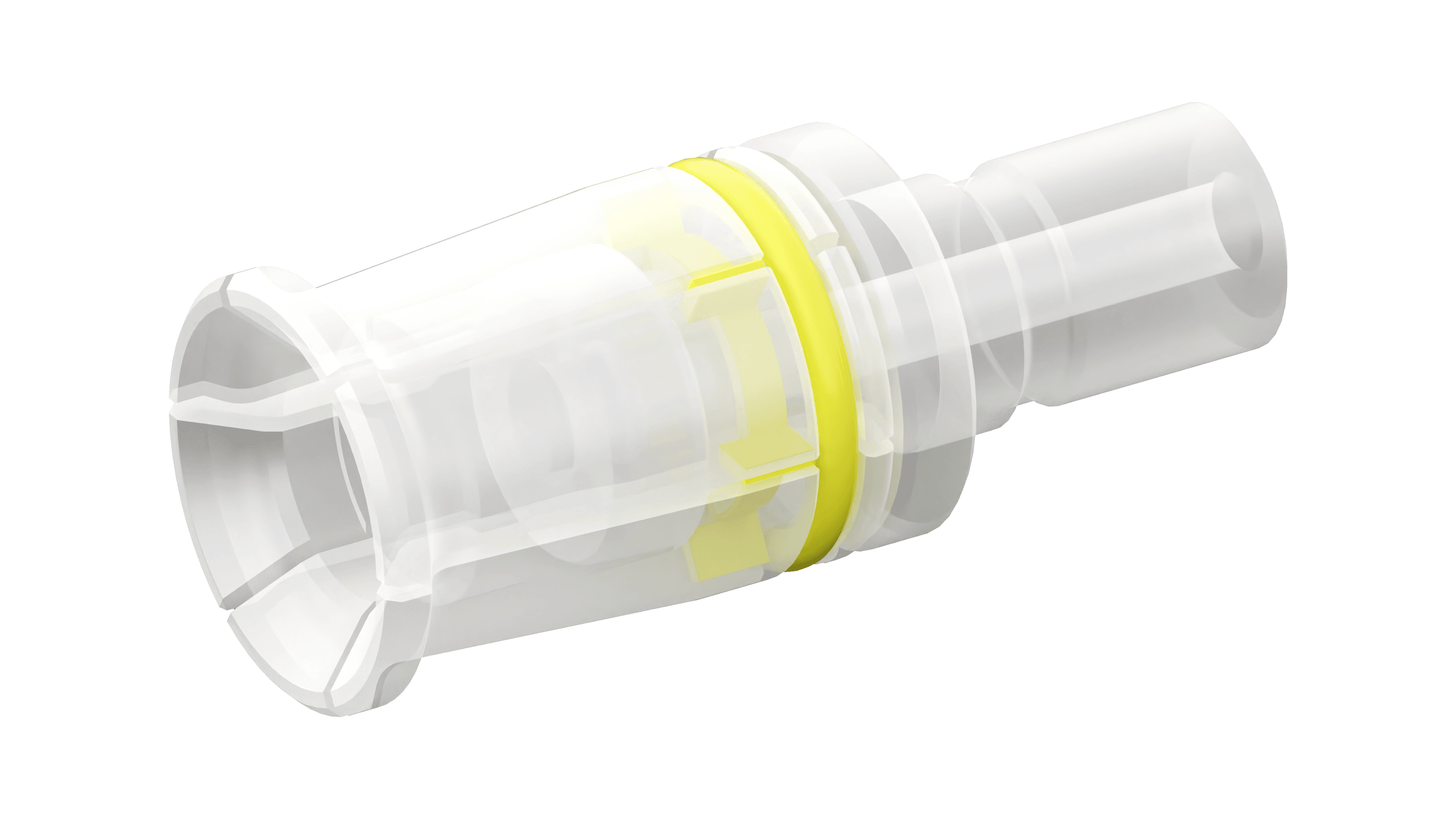

SPANNAX® SlimLine

The through-feed chuck is now even more compact and lighter - ideal for bar machining on the main spindle

QUADRO®

Specially developed for workpiece clamping when using CNC lathes

VarioLine

Ready for Industry 4.0 thanks to the combination of electric drive and stationary clamping technology

Advantages of our clamping systems

Highest concentricity and repeat accuracy for precise machining results

Low-maintenance and robust design – ideal for continuous industrial use

Short setup times thanks to easy handling and precise centering

Customized special solutions tailored to the workpiece, machine, and process

Durable design, developed and manufactured in Germany

The combination of precision, stability, and efficiency makes Ortlieb clamping technology a central component of modern manufacturing solutions.

Quality and manufacturing competence

All clamping systems are developed and produced at the Zell unter Aichelberg site using state-of-the-art manufacturing technology.

High-precision machining centers, automated testing systems, and strict quality controls ensure consistently high product quality.

The result is clamping solutions that set standards worldwide - robust, durable, and designed for maximum repeatability.

Clamping technology ->